Gear Master was constituted on 18 June 2001 by Mahesh Garg and Shri Krishna Joshi, after giving up a job in a professionally Managed Gear Manufacturing Co.

Mahesh Garg – A Metallurgist, specialist in heat treatment, and an expert in Gear manufacturing for 20 years with proven record of success and achievements in different projects such as converted shot blasting into shot pinning, procedure for development of anti - carburizing paste for heat treatment and import substitution.

Mr. Shri Krishna Joshi – A specialist in Gear application and Gear Box selection for 12 years as marketing manager and had satisfied diverse customers form Port, Textile, Steel, Cement, Sugar, Plastic, Soya, Detergent, Cooling Tower OEM & Consultants.

Since both of us shared similar values and beliefs and a strong relationship quickly a joint venture agreement came into existence.

The Duo team knows the market had vast knowledge & experience coupled with enthusiasm & vision documented a business process map and set about to launch.

The response had been overwhelming excellent support received from all our customers by giving us an opportunity for complete Gear Boxes and spares. This all was highly motivating to open up new horizons.

What are the facilities available with Gear Master ?

We have turning, hobbing (teeth cutting) heat treatment, teeth & profile grinder, bore grinder, inspection facilities.

What are the products and their range available with Gear Master ?

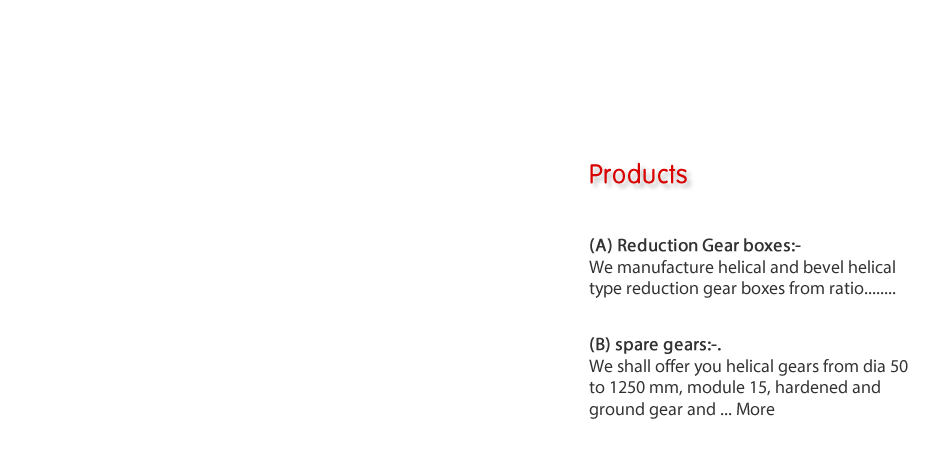

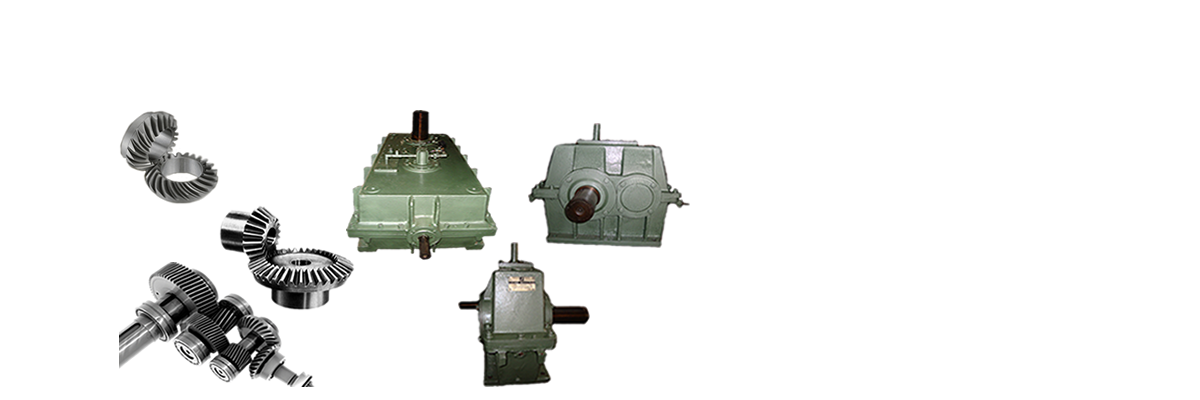

#) Helical & Bevel Helical standard Gear Boxes.

#) Helical & Bevel helical Gear Boxes as per your drawings or specifications.

#) Helical Gear as spare for leading brands of gear boxes: size 25 mm dia to 1250 mm dia. Module up to 16, hardened & ground. Spiral Bevel gear up to 800 mm dia, lapped.

Our quality is comparable to any leading Gear manufacturer.?

Our quality is comparable to any leading Gear manufacturer.

We at Gear Master are deeply involved in inspection and quality assurance right form the procurement of gear material to the forge shop to machining to heat treatment to grinding to final inspection as per our most stringent specification.

We strictly follow every step of our quality plan and stage wise inspection during manufacturing.

Why should I buy Gear & Gear Boxes from Gear Master ?

On your specific requirement we visit your works, study your requirement and offer you the most accurate Gear solution to match your needs.

We quote our most competitive offer & look forward for your valuable order; on supply of the order our scope of supply shall also include the supervision of assembly & keeping in touch with the user to watch the performance.

What do I do to place an order for a gearbox with Gear Master ?

For the selection of right size of gearbox we need a few details as per our Data Sheet , shall send you on request or shall visit you plant meet the user dept. quote is submitted thereafter.

What do I do to place on order for spare gears with Gear Master ?

Over a period of time it is learnt that gearbox manufacturer keep on changing the gear & pinion parameters and generally not available ex stocks.

We need the sample for reverse engineering.

What happens in case sample is not available ?

In case sample is not available shall visit and collect the required data.

What are optional Benefits ?

When economy is the order to the day in any industry.

We offer very precise & competitive solutions that meet customer’s needs in an economical manner.

What is the performance guarantee ?

We shall stand guaranteed for 12 months in Gear Boxes and 6 months in spares for the material & workman ship from the date of installation.

What is the motto at Gear Master ?

Professionalism...!

Value for money...!

Innovation...!

Use of technology...!

What should I do next? For complete gear solutions please Contact us on :-

Landline :

0731-2555512 or Mobile : 98262-95258. or fill our Data Sheet and we'll

get back to you with best possible solution........!